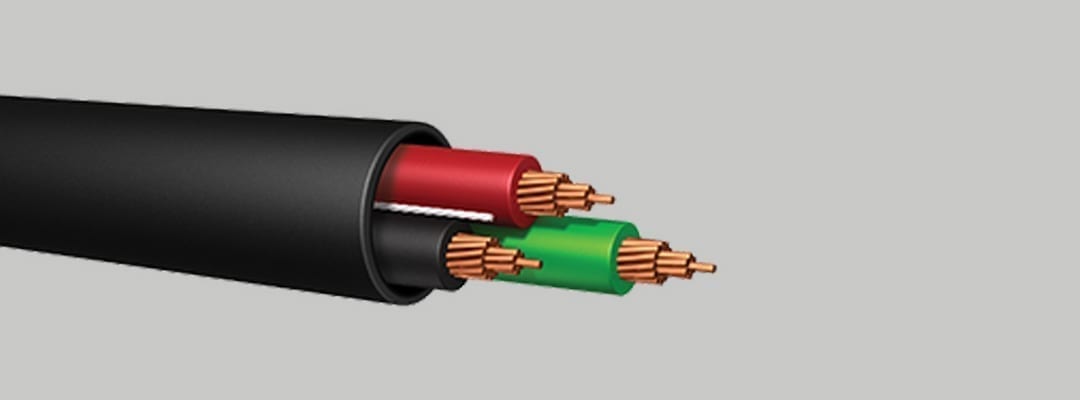

TC-ER and direct bury cable are two types of tray cable used by electricians.

Tray cable is cable that’s approved for installation in cable trays or raceways. Because of its versatility, tray cable has applications in the utility, light industrial and construction industries.

TC-ER and direct bury cable offer different levels of protection from impact. Depending on your situation, one type of tray cable may be better than the other.

What is TC-ER Cable?

TC-ER cable refers to exposed run or ER-rated tray cable. TC-ER cables are out in the open instead of being buried underground where they are protected from wear and tear.

Because they are more vulnerable to impact, TC-ER must pass more stringent requirements for crushes and impacts before they can be used on a utility job.

TC-ER can go directly from the cable tray to the equipment it is powering. However, because it is exposed, the cable must be supported every six feet. Tray cables with an ER rating can be used up to 50 feet outside the tray without the need for additional armor if given proper support.

The advantage of having TC-ER cable is that it can decrease or eliminate the need for conduit between a cable tray and an electrical device. TC-ER is also less expensive than standard tray cable. When used in a project design, it could lead to a large reduction in cost for the entire project.

What is Direct Bury Tray Cable?

As the name suggests, direct bury (DB) rated tray cables allow you to bury tray cable underground.

A DB cable has been tested for its resistance to moisture, so water can’t find its way into the dirt and make contact with the equipment. Once it has passed all the specifications, the cable can be buried in a trench. You can then connect it to equipment that needs powering but would otherwise require conduit.

The advantage of DB tray cables is that they are built with more rigid jackets, meaning they can withstand greater force. Though TC-ER is subject to more wear and tear, the cables buried underground will be stepped on more often.

Because of these rigid jackets, DB cables have a higher crush and resistance impact threshold than their counterparts.

The Difference Between Class I Division I and Class I Division II Cable

Class 1 Division 1 (2104 NEC 500.5)

This cable is designed for areas where there is or may be an explosive atmosphere of gases or vapors mixed with air present during normal operation, for any reason.

Class 1 Division 2 (2014 NEC 500.5)

This cable is designed for areas where there is an explosive atmosphere of gases or vapors mixed with air when an abnormal condition exists, such as failure of a containment wall or ventilation system.

The site designer and local inspectors determine which class should be used, and the contractor should determine the division. Your distributor does not determine which class and division of products to use.

Standards and Guidelines

UL Requirements

UL 83 – Thermoplastic Wire and Cable

UL 44 – Thermoset Insulated Wire and Cable

UL 1277 – Electrical Power and Control Tray Cable

UL Requirements for Sunlight Resistance and Direct Bury

IEEE 1202 (70K BTU/Hr) Vertical Tray Flame Test – FT4 Canadian Equivalent

CSA 22.3 for -40 Cold Bend – 35 Cold Impact Requirements

Industrial and Utility Standards

NFPA 70 – NEC 336

NEMA WC57/ICEA S-73-532

ICEA T-29-520 210,000 BTU/Hr Flame Test

Border States Stocks and Cuts Tray Cable

Border States is authorized to stock these cables in all locations. See all available products in our Wire and Cable catalog.

Border States offers a suite of services and solutions, including but not limited to: wire and cable cut-to-length and paralleling, specialized wire and cable reels, wire and cable scrap services, wire and cable pulling heads, and cable management programs. Learn more about our custom wire services here.

This article was originally published on April 12, 2017. It was updated and republished on April 28, 2021.