What is hand-arm vibration syndrome?

What is hand-arm vibration syndrome?

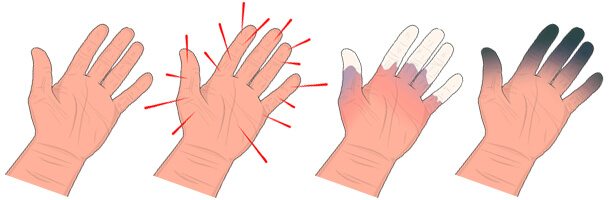

When conducting an anti-vibration gloves review, it’s important to remember hand-arm vibration syndrome (HAVS) is a genuine affliction that largely affects workers who operate vibrating machinery on a regular basis.

Some of the higher HAVS risk occupations include construction, sheet metal work, welding, automotive repair and electrical work, but smaller tools such as hand saws and power drills can still contribute to more modest HAVS. Whether it’s weed eating, pushing a lawnmower around the yard or going for a lengthy bike ride, there’s a good chance you’ve experienced this tingling and numbness in your hands and arms.

Even professions in the medical and dental fields carry some risk, due to the prevalence of machinery that produces high-frequency vibrations. If a job requires the regular use of any machinery that vibrates at all, the potential exists of developing HAVS to some extent or another.

HAVS is more dangerous than you think

HAVS is more dangerous than you think

While occasional use of vibrating machinery may only cause numbness and tingling for a few minutes or hours, regular use can lead to severe cases of HAVS that can be both debilitating and irreversible. An individual could suffer a loss of grip strength, decreased dexterity, arthritis, tendonitis, carpal tunnel syndrome or chronic pain.

Here are some easy ways to fight HAVS:

- Use anti- or low-vibration tools.

- Hold them as loosely as possible and in multiple positions.

- Ensure those tools are well-maintained and inspected regularly.

- Take regular 10-minute breaks.

- Keep yourself (especially your hands) warm at work.

- Rotate workers so no individual worker has prolonged or repeated exposure to vibration.

- Add anti-vibration materials to your list of personal protective equipment (PPE).

Anti-vibration gloves review: They work

Anti-vibration gloves review: They work

Although wearing gloves may seem like a common-sense preventive measure, choosing the right kind of gloves can make a significant difference. Finding the right hand protection is one in a list of best practices safety experts recommend for reducing long-term damage.

NOTE: Just because a glove claims to have anti-vibration properties doesn’t mean it’s actually been third-party tested to meet ANSI/ASA S2.73/ISO 10819 requirements – the global standard for anti-vibration gloves. Gloves should feature padded palm technology that reduces vibration.

ANSI/ISO standard anti-vibration gloves also require:

- Full-fingered design

- Uninterrupted palm pad from base to fingertips

- Padding less than 8mm thick in the palm and greater than 0.55 times the palm padding thickness in the fingers and thumb

Take hold of safety with anti-vibration gloves

Take hold of safety with anti-vibration gloves

No amount of prevention and common sense can stamp out equipment vibration entirely. Some tools and equipment are just necessarily constructed to vibrate. However, it’s important to take the right measures by wearing proper hand protection. Learn more about anti-vibration gloves.

This blog post was drafted in partnership with Ergodyne. Check out Ergodyne’s original article, “Why wear anti-vibration gloves?” as well as their helpful Vibration Hazard page.

Related posts

Thermal winter work gloves provide quality insulation in extreme cold

Fog-resistant safety glasses ideal eyewear technology for any job site