If reducing maintenance, repair, operations and warehouse expenses is at the top of your to-do list this year, implementing industrial vending machines with a distributor stocking partnership could help you achieve your goals.

Reduce Material Usage and Improve Inventory Management Processes

Industrial vending machines are proven to reduce the impact consumable products have on your budget by reducing material usage, stockouts, freight charges, purchasing and receiving expenses.

Take back the control of your consumable materials and stop the leakage of spend on everyday products like safety glasses, batteries and gloves. Items like these work well with the automatic dispensing nature of the machines.

With vending, you select the materials—like these highly consumable products—you would like to be placed in the machine, or your stocking partner can provide recommendations if you are unsure.

Once your materials are placed in the machine, you have the ability to track their usage with built-in machine analytics. Otherwise, you could let your distributor optimize and automate the entire process from procurement to receiving.

Access and Shrinkage: Accountability for Your Users

Do you have unstaffed storerooms or situations where it is not cost effective to staff them?

Whether your unstaffed storeroom is unlocked or locked, your industrial vending machines will reduce the walk-around time of your maintenance employees who access material while reducing your material shrinkage.

Vending machines solve the access and shrinkage problems by providing 24/7 secure access to multiple types and sizes of materials. This allows your employees access to the right products at the right time.

Focus Your Employees’ Time on Essential Projects

Vending solutions customized to meet the individualized needs of your facility create efficiencies and competitive advantages for your business.

Are there projects across your facility with inconvenient access to storerooms? Remove the materials management focus of your employees and return it their core competencies by placing materials closer to the point of use in a vending machine.

Cut Back on Your Consumable Material Spend

The largest benefit of a vending solution is reduction in material spend.

This occurs because materials found in industrial vending machines are sometimes used 30 percent less than if placed in traditional storerooms.

Prove It for Yourself

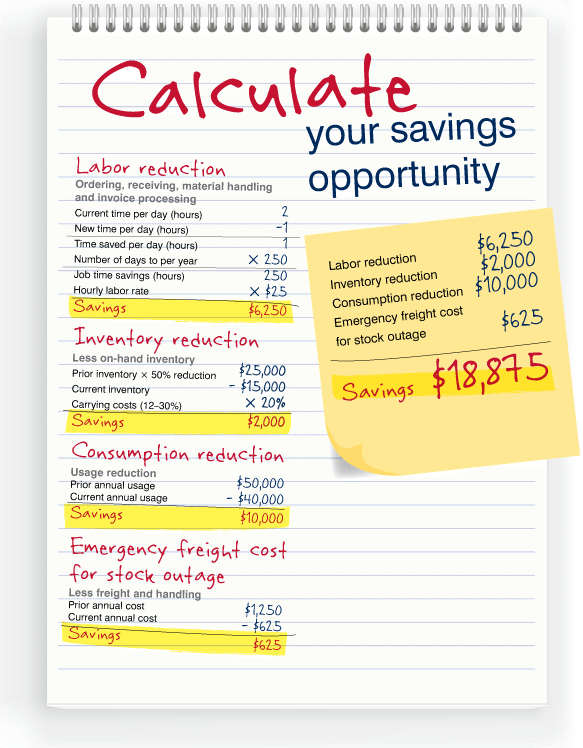

Calculate your industrial vending machine savings. Here are some common cost savings calculations in which you can apply your own numbers to calculate your savings opportunity.

Consider vending to reduce maintenance, repair, operations and warehouse expenses. You can remove material receiving and stocking replenishment costs by eliminating material security and traceability concerns using industrial vending.

As always, Border States is here to help if you have any questions about industrial vending machines or any inventory management issue. Schedule a free consultation to learn more.