Safe work sites are the results of clear communication, employee understanding and reliable equipment. Without one of these three key components, pipeline workers and welders could face dangerous conditions. Communication, both on and off site, is of particular importance when it comes to welding.

Oral Communication

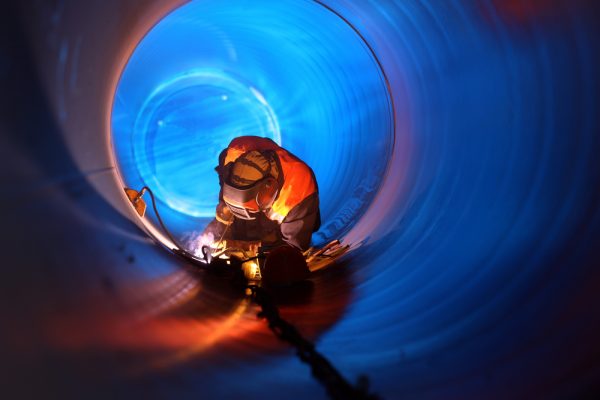

Welders are responsible for building and repairing pipelines, impacting structural integrity and strength. They must be comfortable communicating clearly and regularly with other workers around them. Workers should not be fooled into thinking that all communication takes place at a physical site. According to the Human Resources and Skills Development group in Canada, asking questions and speaking up about any and all concerns during training, whether in-person or hands-on, is essential in ensuring all workers are familiar with expectations and realities. Again, during the course of a welder’s career, he or she may encounter welding assignments that do not make sense initially or that require the workers to do something unfamiliar. At this point, welders need to speak up in order to receive further instruction or a demonstration regarding unfamiliar tasks.

Written Communication

Often, documentation or directions will use symbols to identify the exact type of weld that needs to be completed. If these instructions are not clear, welders run the risk of damaging the pipeline and causing harm to co-workers in the area. Miller, the world’s largest arc welding equipment manufacturer, stated that, in addition to clear oral communication, written safety policies need to be in place for all workers to refer to and follow. In an industry where both efficiency and quality have to be adhered to on a daily basis, there is no room for lax practices. Putting emergency response plans and equipment manuals in writing for all employees to use is essential to building a safe work environment.

Maintaining Consistency

Inspectioneering also noted that different departments and groups working together on the same site must be in constant communication to uphold the integrity of the work. Inspections completed by different parties should be compared to ensure one is not missing a crucial piece of information that could change the others’ observations. In addition, if any issues are spotted, welders need to be informed immediately, and inspectors must make sure workers understand why certain policies are in place and how to fix problems as they arise in the future.

Upholding Tradition

From a completely different perspective, clear communication is necessary to keeping the welding craft alive. As North American Oil & Gas Pipelines stated, the welding profession is slowly dwindling. Due to the rising importance placed on millennials in the past decade or two, more often than not, young people opted for four-year degrees and shied away from industry jobs, like welding.

As many of the most skilled welders in the industry approach retirement, they are constantly looking for subjects to whom they can teach their welding craft. In fact, many manufacturers offer hands-on training courses for young people interested in welding. These courses provide opportunities for more experienced welders to communicate their skills and talents to the next generation.