Performing maintenance on machines or equipment that circulate hazardous energy can lead to serious or fatal injuries if not operated under regulated, safeguard procedures — commonly known as lockout/tagout (LOTO) procedures. Hazardous energy can present itself in many forms (e.g., electrical, chemical, hydraulic, mechanical, thermal and pneumatic), and it can cause equipment to start up unexpectedly or release stored energy, which puts workers’ safety at risk if LOTO guidelines are not followed.

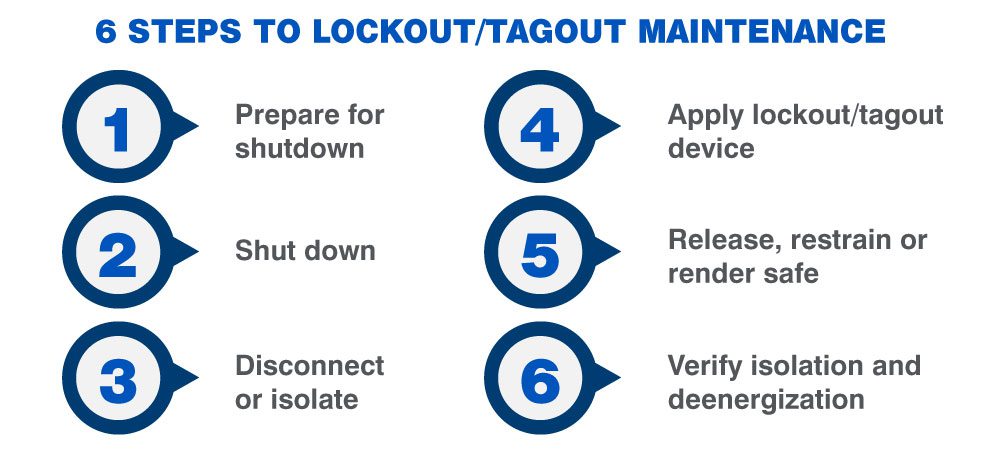

According to the Occupational Safety and Health Administration (OSHA), workers are encouraged to learn about and be prepared to execute the following six steps of LOTO when handling energy-powered equipment.

1. Prepare for shutdown

Before shutting down the machine or equipment and performing maintenance, it’s important to investigate, determine and understand what type(s) of hazardous energy is involved and plan accordingly. This step is crucial for safely controlling unpredictable, stored energy.

2. Shut down

Shut down machinery or equipment for maintenance. During this step, you should also inform affected parties of the shutdown, so they can prepare according to respective shutdown procedures.

3. Disconnect or isolate

Disconnect or isolate the machine, ensuring it is secluded from all sources of energy (e.g., turn power off, close valves, etc.).

4. Apply lockout/tagout device

After confirming that the machine or equipment is isolated, an authorized worker must attach the LOTO device(s).

Performing a lockout means to place a lock on the machine or equipment that needs maintenance, which prevents the risk of an unexpected startup. When applying the lockout device, be careful to apply it in the “off” or “closed” position.

Once the machine or equipment has been locked, the authorized worker will proceed to add tags to the device (a.k.a., “tagout”). Tagout is performed by placing a tag on the equipment’s shut-off device, noting the authorized worker’s name and contact information if others have questions related to the locked equipment.

Remember, it’s critical that all equipment or devices affiliated with the LOTO are managed and/or handled only by authorized workers.

5. Release, restrain or render safe

Although the isolation steps have been completed by this point, there is still a risk of hazardous energy being stored in the machine, which could make it unsafe to perform maintenance. Take the time to check for stored or residual energy — release, restrain or disconnect the energy before rendering it safe.

6. Verify isolation and deenergization

Finally, verify that all steps and precautions have been taken to isolate the machine or equipment, lock out any components that could unexpectedly start up and check for stored energy. It’s important that you have the utmost confidence and assurance in your safety before moving forward with maintenance.

Post maintenance

After performing maintenance, replace safety features, remove all locks and tags, inform affected workers that reparations are complete and prepare for restoration. Before reenergizing the equipment, direct workers to put a safe distance between them and the equipment and prepare for startup. Once startup is complete and you have ensured the equipment is running properly, you’re back in business!

Review these six steps and OSHA guidelines for lockout/tagout (LOTO) procedures regularly, so you can keep yourself, colleagues and equipment as safe as possible in the presence of hazardous energies.

Read more

What the Five Types of Safety Controls Look Like in Practice