Power-limited tray cable (PLTC) is a low-energy instrumentation tray cable limited to 300 V. When most people think of instrumentation applications, they are referring to PLTC.

Instrumentation tray cable can be rated for either 600 V or 300 V, but both types must meet specific requirements for crush resistance. Given size and use, measuring up to the standards can be difficult in cables using smaller conductors.

NEC 725 allows for PLTC to be used in industrial settings and calls for instrumentation cable to be installed between a cable tray and the equipment or device without the use of conduit. On the control side, instrumentation tray cable can be used for turning systems off and on as relays, such as breakers and other switchgear.

What is PLTC used for?

Applications for PLTC include burglar alarms, business machines, power-limited circuits, intercom systems and cash registers. It can also be used in petrochemical refineries, mass transit and other industrial control systems. Its most common application, however, is in utility substations.

PLTC is available in several configurations. It can be wired via direct burial, open trays, free air or troughs with continued rigid cable support. PLTC maintains efficiency when encased in concrete.

PLTC and Other Instrumentation Tray Cable

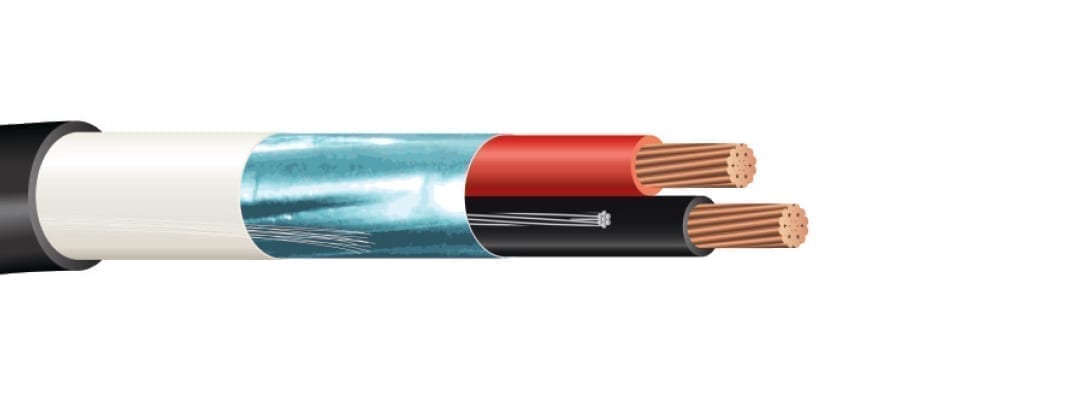

1. Conductors

- Size/gauge varies

- Number of pairs or triads varies

- Pair: two conductors twisted together

- Triad: three conductors twisted together

2. Shielding

- Shield with drain wire

- Individually shielded pairs or triads with drains and an overall shield with drain

3. Insulation

- PVC

- EPR

4. Jacket (most common types)

- PVC

- CPE

- CSPE

5. Voltage

- 300 V PLTC instrumentation cable

- 600 V instrumentation tray cable

6. Applications

- Suitable for use in Class I Division II hazardous locations

- UL approved as sunlight-resistant and suitable for direct burial applications

Difference Between Class I Division I and Class I Division II Cable

Class 1 Division 1 (2104 NEC 500.5)

This cable is designed for areas where there is or may be an explosive atmosphere of gases or vapors mixed with air present during normal operation, for any reason.

Class 1 Division 2 (2014 NEC 500.5)

This cable is designed for areas where there is an explosive atmosphere of gases or vapors mixed with air when an abnormal condition exists, such as failure of a containment wall or ventilation system.

The site designer and local inspectors determine which class should be used, and the contractor should determine the division. Your distributor does not determine which class and division of products to use.

Standards and Guidelines

UL Requirements

UL 83 – Thermoplastic Wire and Cable

UL 44 – Thermoset Insulated Wire and Cable

UL 1277 – Electrical Power and Control Tray Cable

UL Requirements for Sunlight Resistance and Direct Bury

IEEE 1202 (70K BTU/Hr) Vertical Tray Flame Test – FT4 Canadian Equivalent

CSA 22.3 for -40 Cold Bend – 35 Cold Impact Requirements

Industrial and Utility Standards

NFPA 70 – NEC 336

NEMA WC57/ICEA S-73-532

ICEA T-29-520 210,000 BTU/Hr Flame Test

Border States Stocks and Cuts Tray Cable

Border States is authorized to stock these cables in all locations. We offer a suite of services and solutions, including but not limited to: wire and cable cut-to-length and paralleling, specialized wire and cable reels, wire and cable scrap services, wire and cable pulling heads, and cable management programs. Learn more about our custom wire services here.

Call and let us help meet all of your product and solution needs (866-483-7289).

This article was originally published on May 3, 2017. It was updated and republished on June 29, 2021.

Read more:

What Is Tray Cable? Everything You Need to Know

Power and Control Tray Cable: What are the Best Applications?

TC-ER and Direct Bury Cable: What are the Differences?