By Kurt Goodermote, PPE Test Lab Technician Lead

One of the most important pieces of safety protection for people who work with electric power is high-voltage rubber gloves. The proper care and testing of rubber gloves (and other equipment) will keep people safe in a dangerous line of work. Following Occupational Safety and Health Administration (OSHA) rubber glove testing requirements protects the safety of every worker, every day.

What You Should Know About OSHA Rubber Glove Testing

How often should electrical gloves be tested?

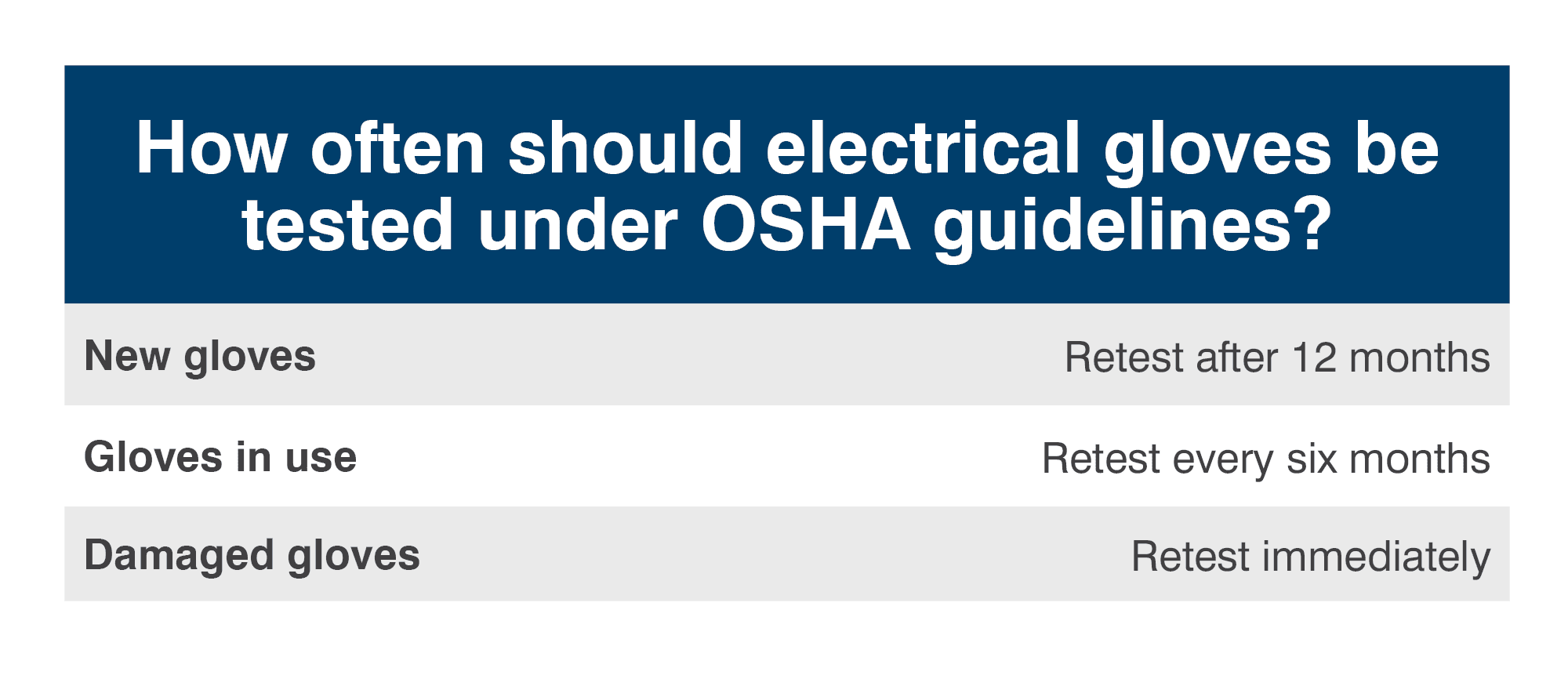

OSHA requires rubber glove testing on a very specific schedule. This makes it easy to comply, and more importantly, increases the safety of you and those around you.

- New gloves (never issued to anyone): New rubber insulating gloves have 12 months before they are required to be retested. Once they are put into use, they must be tested within six months of the date they were issued. Gloves are stamped with a date to help manage this regulated schedule.

- Gloves in use: Rubber insulating gloves can be used for six months after the test date on the glove. Once this date is reached, they must be tested before use. If the gloves were not issued into service after their last test date (i.e., they remained on a shelf), they still expire six months after the test date and must be tested again before use.

Don’t forget that in addition to regular testing, you must do daily inspections. Referencing ASTM F1236-96 (2012), OSHA stipulates in 29 CFR 1910.137(c)(2)(ii) that all insulating equipment must be inspected for any damage before each day’s use and immediately following any incident that can reasonably be suspected of causing damage.

This step is not only required, but it also absolutely increases safety. Beyond daily inspections, daily cleaning and safe storage methods ensure a safe workplace. By cleaning and then inflating and rolling, you can expose imperfections — such as scratches, punctures or cracking in the rubber. If it doesn’t pass visual inspection, discard the item or have it tested.

Note: High-voltage electrical gloves must meet and/or exceed the performance and testing requirements of the ASTM International ASTM D120-21 – Standard Specification for Rubber Insulating Gloves and the International Electrotechnical Commission (IEC) 60903:2014 Live Working – Electrical Insulating Gloves standard.

Where can I find OSHA-compliant rubber glove testing?

Border States offers rubber glove testing. At our lab, we follow American Society for Testing and Materials (ASTM) standards to ensure proper testing and compliance. ASTM is a developer of international standards, and ASTM standards are OSHA compliant. Keeping these standards and adhering to regular care and maintenance keeps workers safe and reduces the risk of an OSHA fine.

Make sure you have your gloves and other equipment tested by someone who also follows ASTM standards to be OSHA compliant and safe.

How does testing work?

Electrical safety gloves must incorporate dielectric properties (not conducting electricity), strength, flexibility and durability. Over time, these properties may change or fail, making the article unsafe.

- Cleaning – Gloves are meticulously cleaned of all dirt and grime before testing.

- Visual inspection – The gloves are inflated and rolled to reveal any damage, such as small holes, tears or cracking.

- Electrical testing – The rubber glove is exposed to electrical voltage based on the rubber’s class (ASTM F496: Section 7) and tested beyond its maximum field use. If it fails, it is stamped as a failure.

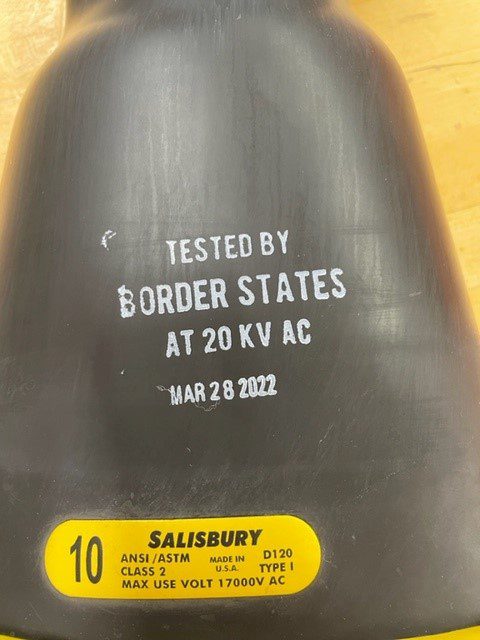

- Certification – Once the item passes the visual and electrical test, it can be stamped as certified.

- Date stamping – Special ink is used for the stamping of the certified glove. The ink will not fade or wipe off during normal use.

Below is an example of a rubber glove that has been certified and stamped:

How should I ship my gloves?

Don’t pack gloves and sleeves too tightly because this may crease the material and put them in a condition that will not pass testing.

What other rubber goods need to be tested regularly?

In addition to rubber insulating gloves, you also need to test:

- Rubber insulating sleeves (must be tested every 12 months)

- Rubber insulating blankets

- Rubber insulating matting

- Rubber insulating covers

- Rubber insulating line hoses

MSHA rubber glove standards

If you are in the mining industry, you must also comply with rules by the Mine Safety and Health Administration (MHSA). MSHA is an agency under the Department of Labor that works to prevent illness, injury and death by promoting safe work practices for U.S. miners.

MSHA laws take precedence over OSHA’s. However, if MSHA has no standards applicable to working conditions on a specific site, then OSHA regulations will be applied.

In some cases, MSHA requires rubber gloves to withstand higher voltage and be tested more frequently. For example, employees working on high-voltage surface lines must have their rubber gloves tested to 20,000-volt dielectric strength once per month. For more information, read MSHA Requirements of Testing High-Voltage Gloves.

Rubber Glove Testing Saves Lives

Working where there is the potential for extreme electrical hazards requires adequate protective gear and approved, regular testing methods in place. Testing ensures that these properties remain, prevents injury or loss of life and eliminates OSHA fines. Please reach out to us for all your testing requirements to protect the safety of every worker, every day.

Read more:

Top OSHA Violations: Analyzing Historical Data and Advocating for a Future Built on Safety

67 Toolbox Talk Topics: Critical Safety Shares to Emphasize with Your Team